Looking for a fowler precision? Have a look at this 2019 guide!

When you want to find fowler precision, you may need to consider between many choices. Finding the best fowler precision is not an easy task. In this post, we create a very short list about top 10 the best fowler precision for you. You can check detail product features, product specifications and also our voting for each product. Let’s start with following top 10 fowler precision:

When you want to find fowler precision, you may need to consider between many choices. Finding the best fowler precision is not an easy task. In this post, we create a very short list about top 10 the best fowler precision for you. You can check detail product features, product specifications and also our voting for each product. Let’s start with following top 10 fowler precision:

Best fowler precision

1. Fowler 54-554-622 Internal Electronic Caliper Gage, 0.200-1" Measuring Range, 0.005" Resolution, 0.0008" Accuracy

Feature

Plastic body, steel arms, and hardened steel contact point for durabilityAccuracy of 0.0008"/0.02mm and 0.0002"/0.005mm resolution for precise measurements

Absolute and incremental modes for taking intermediate or differential measurements

Direct RS-232 output for data transfer

Description

The Fowler Internal Electronic Caliper Gage measures inside dimensions (ID) with 0.0008"/0.02mm accuracy and 0.0002"/0.005mm resolution, and has a digital, single-value readout LCD, absolute and incremental modes, and RS-232 output. This caliper measures ID for hole diameters and groove and tube thicknesses. The digital, single-value readout LCD shows inch and metric units for versatility when measuring. The unit offers absolute and incremental modes for taking intermediate or differential measurements and stores a preset reference for comparing measurements. The caliper is spring-loaded in the measuring direction for a consistent measuring force and improved measurement repeatability. A thumb lever retracts the movable point. This caliper can output data via direct RS-232 for capturing and recording data. The caliper has a 2"/5cm diameter plastic electronic housing, steel arms, and hardened steel contact point for durability. The caliper uses a 3V CR2032 battery (included). It also comes with an aluminum case with foam inserts to cushion the instrument. Digital calipers are measuring instruments commonly used for inspection in manufacturing to provide the precise measurements of an object. A pair of jaws attached to a long beam with a marked scale is used to take inside, outside, and step measurements. An additional depth probe slides along the beam to take depth measurements. One jaw is fixed to the end of the scale, while the other jaw slides along it with gearless precision to take measurements. The reading is electronically generated and displayed on a digital, high-resolution screen as a single value. Digital calipers can take differential measurements that are used to determine the difference in measurements between two objects, by zeroing the display at any point along the scale. Some digital calipers can switch between standard and metric units, and some can output readings to a computer or printer for recording measurements. Caliper gages are used in production settings where specific diametrical or thickness measurements must be repeated frequently with precision and accuracy. Compared to dial calipers, digital calipers provide measurements that are faster, easier, and more error-free, but they are more fragile mechanically and electronically, and do not resist coolant well. Vernier calipers are more durable than digital calipers because they do not have internal moving parts, but they can be more difficult to read. Digital calipers are commonly used in fields such as metalworking, mechanical engineering, machining, carpentry, and medicine.The Fred V. Fowler Company manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages, and digital scales. The company, founded in 1946, is headquartered in Newton, MA.Whats in the Box?Fowler internal electronic caliper gage3V CR2032 batteryAluminum case.2. Fowler Full Warranty Stainless Steel Shockproof Dial Caliper, 52-008-706-0, 0-6" Measuring Range, 0.001" Graduation Interval, Face Color White

Feature

Full 1 year warranty offered by Fowler High Precision, an American companyDial graduations of 0.001" with one revolution equivalent to 0.100"

Hardened stainless steel construction for corrosion resistance and long life, shockproof anti-backlash control with heavy-duty spring for accuracy

Knurled lock screw holds the sliding jaw in position to help ensure a consistent measurement

Covered rack to prevent dirt and debris from clogging the gear, and to help prevent measurement errors

Description

The Fowler Shockproof stainless steel dial caliper has dial graduations of 0.001" with 0.001" accuracy, shockproof anti-backlash control, a sliding jaw with a lock, and a covered rack. This caliper is used for measuring inside dimensions (ID), outside dimensions (OD), depth, and step. This product has a 1 year warranty offered by Fowler High Precision. If you experience any problem contact Fowler directly for warranty claims.

Shockproof spring anti-backlash control with a heavy-duty spring offers increased accuracy over standard gear configurations. Backlash is the amount of clearance between mated gear teeth in the caliper controls that prevents the gear teeth from jamming. It is undesirable to have much backlash due to the lack of precision offered by the increased amount of play between gears. Certain gear designs can minimize or eliminate backlash; spring anti-backlash systems use a spring to add a compressive force, thereby minimizing backlash.

This caliper has a knurled lock screw to hold the sliding jaw in position and help ensure a consistent measurement. A covered rack prevents dirt and debris from clogging the gear, and helps prevent measurement errors. A thumb-operated fine adjustment roller allows for one-handed use.

The caliper measures 0.10" per revolution of the dial. The dial has 0.001" graduations, and the beam has engraved 0.1" graduations. The hardened stainless steel components, including the beam, measuring surfaces, rack, gears, and depth rod, offer corrosion resistance, increased accuracy, and long life. Self-contained movement eliminates gear misalignment, while the dual pinion drive mechanism reduces wear on the rack and pinion. An adjustable dial enables setting zero. The hardened stainless steel is polished to a satin chrome finish, to help prevent glare. This caliper comes with a fitted case.

Dial calipers are measuring instruments commonly used for inspection in manufacturing to provide the precise measurements of an object. A pair of jaws attached to a long beam with a marked scale is used to measure inside, outside, and step measurements in standard or metric units. An additional depth probe slides along the beam to take depth measurements. One jaw is fixed to the end of the scale, while the other jaw slides along it to take measurements. A circular dial indicator is fixed to the movable jaw on a toothed gear rack that transfers movement of the jaws to the dial needle. The base measurement is taken from the long beam, which provides the initial whole measurement in inches or centimeters, and added to the dial reading, which provides fractional measurements in inches or millimeters. A locking mechanism provides the ability to take differential measurements for determining the difference in measurements between two objects. Compared to digital calipers, dial calipers are more durable, but are more susceptible to shock damage and prone to getting dirt in the gears, which can cause accuracy problems. Vernier calipers are more durable than dial calipers because they do not have internal moving parts, but they can be more difficult to read. Dial calipers are commonly used in fields such as metalworking, mechanical engineering, machining, and carpentry.

Fowler, an American company, manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages, and digital scales. The company, founded in 1946, is headquartered in Newton, MA.

What's in the Box? Fowler Shockproof 0-6 dial caliper Fitted case

3. Fowler 54-585-250 Articulating Magnetic Base and Indi-X Blue Fraction Electronic Indicator Set, 0.0005" Indicator Resolution, 85 lb. Pull Magnet

Feature

1 year warranty offered by Fowler High PrecisionDescription

The Fowler 54-565-233 High-Accuracy Ultima Bore Gauging System has a measurement range of 7.878 to 8.27" and is accurate to + or - 0.00006". Resolution is 0.00001" and the measuring depth is 3.15". The gauge has constant spring pressure for repeatability and Bower's FastFit measuring heads for rapid measurement. It uses a three-point contact system for the detection of lobing or triangular form error, and ceramic contact points provide high durability and stability with regard to thermal expansion. The Ultima system requires connection to a Sylvac or multiplexer display unit.This product has 1 year warranty offered by Fowler High Precision. If you experience any problem contact Fowler directly for warranty claims.4. Fowler Full Warranty 52-432-246-0 Machinist Hardened Steel Square Set, 2", 3",4",and 6" Blade Size

Feature

1 year warranty offered by Fowler High PrecisionMade of hardened steel, these economy squares have true right angles both inside and outside

Beams and blades ground and lapped for straightness and parallelism

Length of hardened blade is measured from inner edge of beam to end of blades

Beam grooved at inner corner for clearance of burrs and dirt

Squareness of the blade edge to the working face of the stock is 0.0006" for 2" and 3" models, and 0.0008" for 4" and 6" models

Description

The Fowler 52-432-246-0 Machinist Hardened Steel Square 4 Piece Set is designed for schools, apprenticeships and training programs. Made of high carbon steel, these squares have true right angles both inside and outside. Beams and blades ground and lapped for straightness and parallelism. Grooved at inner corner for clearance of burrs and dirt. This product has a 1 year warranty offered by Fowler High Precision. If you experience any problem contact Fowler directly for warranty claims. Fowler, an American company, manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages and digital scales. The company founded in 1946, is headquartered in Newton, MA.5. Fowler 53-620-010 Height Transfer and Squareness Gage with 7.5" Post

Feature

Measurement range of 0 to 7.5"Large fine adjustment knob for precise control

Hand-operated feed slider with fine-adjustment wheel in base isolates column and indicator from heat and hand pressure

Swivel clamp anchors swivel and indicator for added accuracy

Rust-resistant, satin chrome finish on the scales is glare-free

Description

The Fowler 53-620-010 is a height transfer and squareness gauge with a measurement range of 0 to 7.5", a large fine adjustment knob, a hand-operated feed slider with fine-adjustment wheel in base, a swivel clamp, and a rust-resistant, satin chrome finish. A large fine adjustment knob in the base isolates the column and indicator (sold separately) from heat and hand pressure to provide precise control. A swivel clamp anchors the swivel and indicator for added accuracy. The rear surface of the gauge has a reference to square against a master for checking squareness. The gauge comes with the 7.5" post, indicator rod, and clamp.

Height gauges, sometimes referred to as gages, are precision measuring instruments that travel on a vertical column (also called the beam) to measure and/or mark the vertical distance from the base of an object in fine units. The vertical position of the gauge and its attached pointer are changed by turning a calibrated screw, or one or more feed wheels. Recorded rotations are read from a scale, a dial, counters, and/or an electronic display. A screw clamp holds the pointer to the gauge. The pointer is typically sharpened to act as a scriber, and can be used to mark a position on a workpiece by scratching its surface. On compatible units, the scriber may be replaced by an electronic touch-signal probe. Height gauges are typically used in manufacturing, machining, and mechanical engineering.

The Fred V. Fowler Company manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages, and digital scales. The company, founded in 1946, is headquartered in Newton, MA.

Whats in the Box?

- Fowler 53-620-010 height transfer and squareness gauge

- 7.5" post

- Indicator rod

- Clamp

6. Fowler Full Warranty AGD Indicator and Magnetic Back, 52-520-485-0, 0-1" Measuring Range, 0.001" Graduation Interval, 1" Travel, 2.25" Diameter

Feature

Full 1 year warranty offered by Fowler High Precision, an American companyDial indicator with magnetic back can be positioned on most metal surfaces to measure surface variations in fractions of an inch

2-1/4" dial diameter with continuous 0-100 dial reading, tolerance markers, 0.001" graduations, and revolution counter for a wide range of travel

Stem has 1" travel and carbide ball contact point for a longe measuring range and long life

Magnetic back has a protective coating and is used to position indicator on most metal surfaces, meets AGD Group 2 specifications for dial face diameter

Description

The Fowler 52-520-485 dial indicator has an American Gage Design (AGD) Group 2, 2-1/4" dial face with a continuous dial, a 0-1" measuring range, 0.001" graduations, a revolution counter, and tolerance markers, and is designed to measure surface variations in fractions of an inch. The 0-100 continuous dial with revolution counter has a total measuring range of 0-1" with each revolution equal to 0.1". An adjustable bezel and dial sets the zero reading at any location. Tolerance markers allow operators to observe limits at a glance. The carbide ball contact point provides durability and long life. The magnetic back can be used to mount the indicator on most metal surfaces, and a protective coating provides durability and long life. This product has a 1 year warranty offered by Fowler High Precision. If you experience any problem contact Fowler directly for warranty claims.

Dial readings with three digits, 0-10-0 for example, signify that the indicator has a balanced dial. Dial readings with two digits, 0-100 for example, indicate the dial has a continuous dial. Balanced dials are used for reading the difference from a specific surface reference point. Continuous dials are used for direct readings and usually have a larger measurement range than balanced dials.

| Specifications | |

| Dial face type and diameter | AGD Group 2, 2-1/4" diameter face |

| Dial type and reading | Continuous 0-100 |

| Range and graduations | 0-1" |

| Graduations | 0.001" |

| Revolutions | Up to 10 revolutions, each revolution equal to 0.10" |

| Mounting | Magnetic back |

| Specifications | AGD Group 2 |

Dial indicators are also called dial gauges, probes, and electronic indicators. These precision instruments measure small linear distances and object sizes. The dial magnifies the measurement so that it can be easily read by the human eye. Frequently used in manufacturing, laboratories, and other industrial or mechanical fields, dial indicators are used anywhere a small measurement must be found and recorded or transferred, such as checking the variation in tolerance of a workpiece. Standard dial indicators measure the displacement along the axis of the indicator. Dial test indicators are very similar to dial indicators, except that the axis of measurement is perpendicular to the axis of the indicator. Dial and dial test indicators can be analog, with a mechanical dial, or electronic, with a digital display. Some electronic models transfer the data electronically to a computer for recording and potential manipulation.

Fowler, an American company, manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages, and digital scales. The company, founded in 1946, is headquartered in Newton, MA.

7. Fowler 52-008-018 Stainless Steel Extended Range Dial Caliper, 18" Maximum Measuring, 0.001" Graduation Interval, Face Color Black

Feature

Dial graduations of 0.001", with one revolution equivalent to 0.100"Hardened stainless steel construction for corrosion resistance and long life

Extended range for measurements up to 24 inches

Knurled lock screw holds the sliding jaw in position to help ensure a consistent measurement

Covered rack to prevent dirt and debris from clogging the gear, and to help prevent measurement errors

Description

The Fowler Extended Range stainless steel dial caliper has dial graduations of 0.001" with 0.001" accuracy, can take measurements up to 24 inches, has a sliding jaw with a lock, and a covered rack. Extended beam lengths allow measurements up to 24 inches. This caliper has a knurled lock screw to hold the sliding jaw in position and help ensure a consistent measurement. A covered rack prevents dirt and debris from clogging the gear, and helps prevent measurement errors. This caliper is used for measuring inside dimensions (ID), outside dimensions (OD), depth, and step.

The caliper measures 0.10" per revolution of the dial. The black dial has 0.001" graduations, and the beam has engraved 0.10" graduations. The outside jaw depth is 3.125". The hardened stainless steel components, including the bar, measuring surfaces, rack, gears, and depth rod, offer corrosion resistance, increased accuracy, and long life. Self-contained movement eliminates gear misalignment, while the dual pinion drive mechanism reduces wear on the rack and pinion. An adjustable dial enables setting zero. Spring anti-backlash control offers increased accuracy over standard gear configurations. Backlash is the amount of clearance between mated gear teeth in the caliper controls that prevents the gear teeth from jamming. It is undesirable to have much backlash due to the lack of precision offered by the increased amount of play between gears. Certain gear designs can minimize or eliminate backlash; spring anti-backlash systems use a spring to add a compressive force, thereby minimizing backlash. The hardened stainless steel is polished to a satin chrome finish, to help prevent glare. This caliper comes with a fitted case.

Dial calipers are measuring instruments commonly used for inspection in manufacturing to provide the precise measurements of an object. A pair of jaws attached to a long beam with a marked scale is used to measure inside, outside, and step measurements in standard or metric units. An additional depth probe slides along the beam to take depth measurements. One jaw is fixed to the end of the scale, while the other jaw slides along it to take measurements. A circular dial indicator is fixed to the movable jaw on a toothed gear rack that transfers movement of the jaws to the dial needle. The base measurement is taken from the long beam, which provides the initial whole measurement in inches or centimeters, and added to the dial reading, which provides fractional measurements in inches or millimeters. A locking mechanism provides the ability to take differential measurements for determining the difference in measurements between two objects. Compared to digital calipers, dial calipers are more durable, but are more susceptible to shock damage and prone to getting dirt in the gears, which can cause accuracy problems. Vernier calipers are more durable than dial calipers because they do not have internal moving parts, but they can be more difficult to read. Dial calipers are commonly used in fields such as metalworking, mechanical engineering, machining, and carpentry.

The Fred V. Fowler Company manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages, and digital scales. The company, founded in 1946, is headquartered in Newton, MA.

What's in the Box?

- Fowler Extended Range dial caliper

- Fitted case

8. Fowler Full 2 year warranty Xtra-Range Electronic Caliper, 54-100-312, 0-12" Measuring Range, 0.0005" Resolution

Feature

2 year warranty offered by Fowler High Precision, an American companyExtended measuring ranges of up to 12"/300mm, with 0.0005"/0.01mm resolution for inside dimension (ID) and outside dimension (OD) measurements

Hardened stainless steel frame for corrosion resistance and long life, long jaws permit accessibility when measuring large workpieces

Digital, single-value readout LCD shows inch and metric units for versatility when measuring

Zero setting to take intermediate or differential measurements

Description

Digital calipers are measuring instruments commonly used for inspection in manufacturing to provide the precise measurements of an object. A pair of jaws attached to a long beam with a marked scale is used to take inside, outside, and step measurements. An additional depth probe slides along the beam to take depth measurements. One jaw is fixed to the end of the scale, while the other jaw slides along it with gearless precision to take measurements. The reading is electronically generated and displayed on a digital, high-resolution screen as a single value. Digital calipers can take differential measurements that are used to determine the difference in measurements between two objects, by zeroing the display at any point along the scale. Some digital calipers can switch between standard and metric units, and some can output readings to a computer or printer for recording measurements. Compared to dial calipers, digital calipers provide measurements that are faster, easier, and more error-free, but they are more fragile mechanically and electronically, and do not resist coolant well. Vernier calipers are more durable than digital calipers because they do not have internal moving parts, but they can be more difficult to read. Digital calipers are commonly used in fields such as metalworking, mechanical engineering, machining, carpentry, and medicine.

Fowler, an American company, manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages, and digital scales. The company, founded in 1946, is headquartered in Newton, MA.

What's in the Box?

- Fowler Xtra-Range digital caliper

- Fitted case

9. Fowler 52-480-050 Steel Straight Edges, 18" L x 1.32" W x .150" Thick

Feature

1 year warranty offered by Fowler High PrecisionDescription

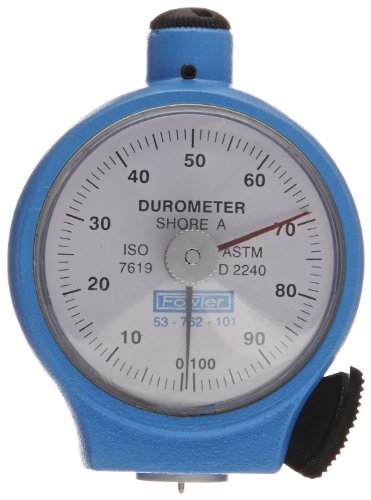

The Fowler 54-565-233 High-Accuracy Ultima Bore Gauging System has a measurement range of 7.878 to 8.27" and is accurate to + or - 0.00006". Resolution is 0.00001" and the measuring depth is 3.15". The gauge has constant spring pressure for repeatability and Bower's FastFit measuring heads for rapid measurement. It uses a three-point contact system for the detection of lobing or triangular form error, and ceramic contact points provide high durability and stability with regard to thermal expansion. The Ultima system requires connection to a Sylvac or multiplexer display unit.This product has 1 year warranty offered by Fowler High Precision. If you experience any problem contact Fowler directly for warranty claims.10. Fowler Full Warranty Economy Analog Portable Durometer, 53-762-101-0, 35 Blunt Taper Penetrator, 1 Shore Graduation, Shore Scale: A

Feature

1 year warranty offered by Fowler High Precision, an American companyManufactured in accordance with DIN, ASTM, ISO and JIS specifications, fits a wide variety of applications

The test piece size should be smooth and have sufficient area to be able to support the base of the hardness tester

Includes reference test block, operating instructions and fitted case

Optional bench stand available

Description

Fowler's Portable Durometer is just right for testing the hardness of flexible materials such as rubber and plastics. These gages conform to shore scales. Test pieces should have a thickness of at least .20"/5mm to provide accurate readings that conform to Shore A hardness scales and at least .12"/3mm for Shore D hardness scales. Manufactured in accordance with DIN, ASTM, ISO and JIS specifications. This product has 1 year warranty offered by Fowler High Precision. If you experience any problem contact Fowler directly for warranty claims.

Fowler, an American company, manufactures inspection and measurement instruments such as electronic indicators, calipers, bore gages, and digital scales. The company, founded in 1946, is headquartered in Newton, MA.